Postion: Home > Our Case > Stamping & Bending >

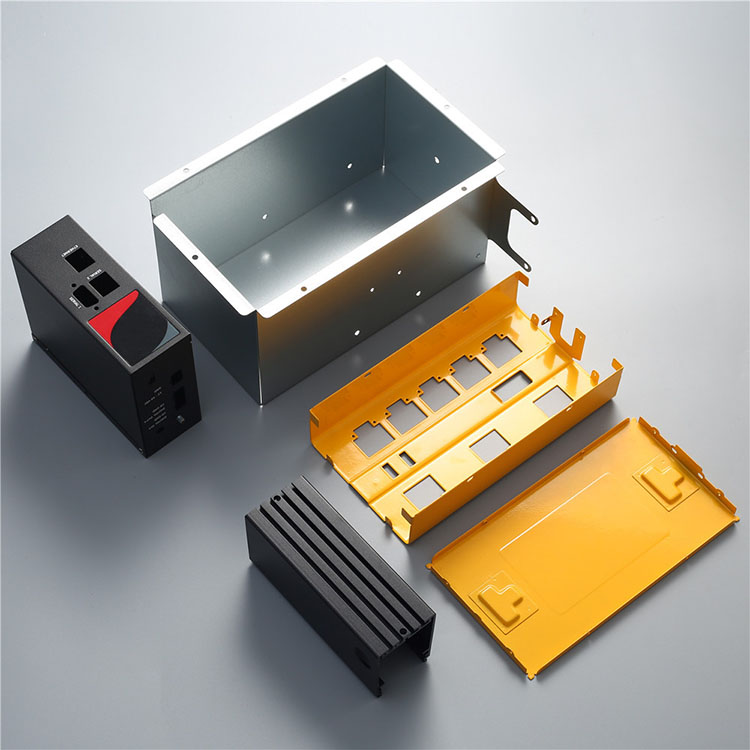

Validate designs quickly without sacrificing accuracy. We prototype single samples to short-run lots with in-house laser cutting, CNC bending, spot/MIG/TIG welding, and finishing ÔÇö all set up for speed and repeatability.

ÔùÅ State revision, material grade, thickness, and finish in the file name or header.

ÔùÅ Mark critical faces/features and bending direction; note cosmetic sides.

ÔùÅ Provide STEP/IGES (3D) + DXF (flat) + PDF drawing with key tolerances.

ÔùÅ Tolerances only where function needs it; keep general dims to a sensible default.

ÔùÅ Aluminum: 5052/6061 for good bendability and weight; 6063/6082 on request.

ÔùÅ Stainless: 304 for general use; 316 for corrosion; 430 for cost-sensitive.

ÔùÅ Steel: SPCC/CRS for painted parts; HS grades on request. Typical 0.8ÔÇô3.0 mm.

ÔùÅ Inside bend radius Ôëê ÔëÑ 1.0├ùT (as a safe starting point).

ÔùÅ Hole-to-bend distance ÔëÑ 1.5├ùT (2.0├ùT preferred for soft materials).

ÔùÅ Minimum flange height ÔëÑ 2.0├ùT + inside radius.

 Slot width  T; keep notches away from bend lines; consider grain direction.

ÔùÅ Use datums, tabs/pins, or small slots for adjustability during assembly.

ÔùÅ Call out fastener types, PEM nuts/inserts, and weld symbols clearly.

ÔùÅ Reserve tight GD&T only for critical interfaces to keep cost/lead time down.

ÔùÅ Powder coat, anodize, passivation, zinc-nickel plating, silkscreen/engraving.

ÔùÅ Provide color codes (e.g., RAL/Anodize Type/Gloss) and masking areas for threads.

ÔùÅ Prototypes typically in 2ÔÇô5 days; short-run lots scheduled per quantity.

ÔùÅ English support with quick DFM feedback and clear progress updates.

ÔùÅ Files: STEP/IGES + DXF + PDF (key dims/threads, finish, cosmetic side).

ÔùÅ Quantity range, target date, and destination country/region.

ÔùÅ Acceptable alternates (e.g., 5052 Ôåö 6061, bead-blast Ôåö polish) if timing is critical.

We sign NDAs on request. Drawings and data are restricted to authorized engineers and handled confidentially throughout prototyping and production.

Tip: If your part has tight bends near holes, attach a detail view with exact distances ÔÇö it speeds DFM and avoids rework.