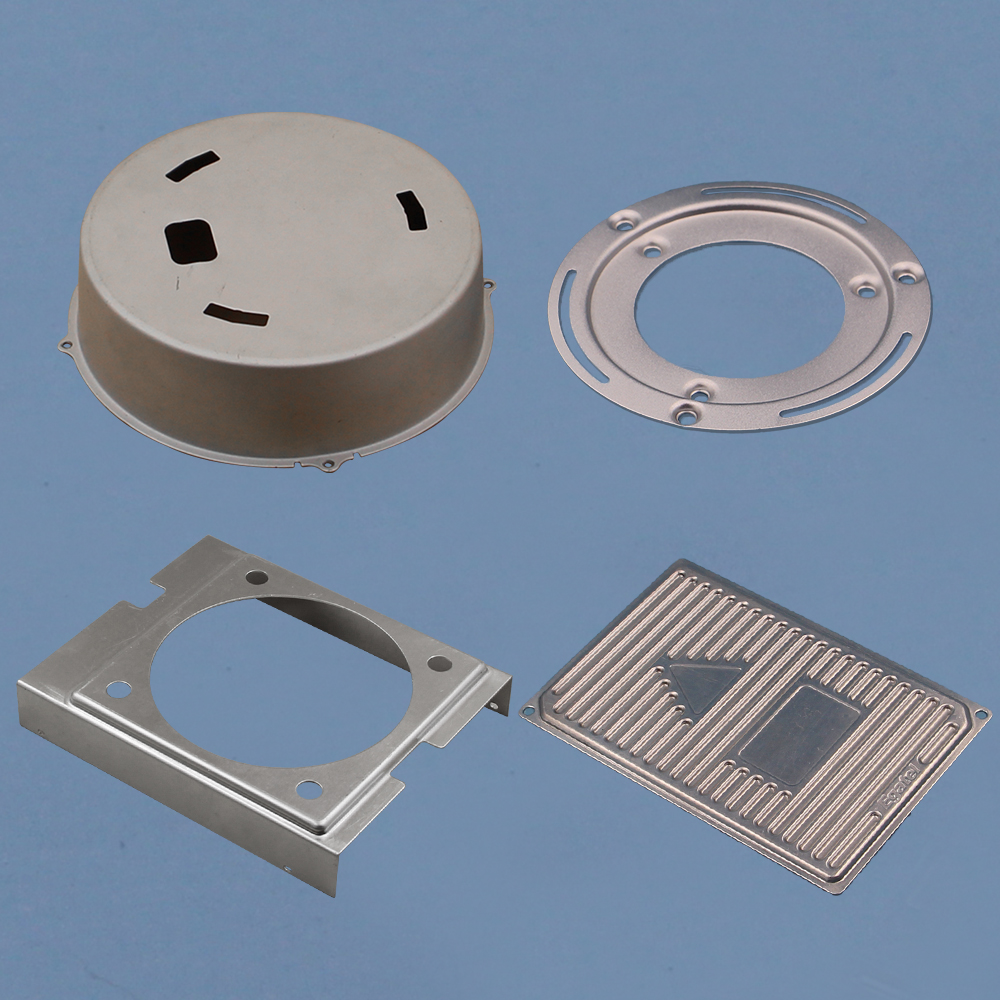

Postion: Home > Our Case > Stamping & Bending >

Global buyers choose China for stamping not only to reduce spend, but to combine scale, stable quality, and fast iteration. If you manage procurement or engineering, hereŌĆÖs how a capable partner makes outsourcing both efficient and low-risk.

Upload CAD & Get Instant Quote

ŌŚÅ Sustainable cost: local steel/aluminum supply, efficient tooling build, optimized nesting to reduce scrap.

ŌŚÅ Consistent quality: ISO-style control from IQC ŌåÆ IPQC ŌåÆ FQC; CMM/vision checks on critical dimensions.

ŌŚÅ Engineering support: English-speaking engineers provide DFM, thickness/tolerance advice, and quick ECOs.

ŌŚÅ Flexible capacity: pilot runs to mass production; fast changeover for urgent orders.

ŌŚÅ Incoming material certs; heat/lot traceability on request.

ŌŚÅ Surface treatment control (zinc-nickel, anodize, powder coat) with salt-spray or adhesion tests when needed.

ŌŚÅ Optional documentation: FAI/PPAP level, ROHS/REACH statements, hardness and plating thickness reports.

ŌŚÅ Samples: 7ŌĆō10 days for simple tools; progressive die build typically 2ŌĆō4 weeks depending on complexity.

ŌŚÅ Packing & shipping: export-grade packaging, express/air/sea options; commercial invoice & packing list prepared.

ŌŚÅ Right-sized tooling (single-hit vs. progressive) based on annual volume and part mix.

ŌŚÅ Shared tool maintenance plan and preventive die care to keep yield stable over time.

ŌŚÅ Files: STEP/IGES + PDF drawing with key tolerances and threads.

ŌŚÅ Material & finish: grade/spec (e.g., SPCC, 304, 5052) and plating/coat.

ŌŚÅ Volumes: prototype, batch range, or annual forecast; target delivery date and destination.

Hongming Sheng signs NDA on request. Drawings, tooling, and data are accessible only to authorized engineers. Your designs remain confidentialŌĆöalways.

Tip: If timing is tight, include acceptable alternates for thickness/finish to speed DFM.