Postion: Home > Our Service >

Our Service

Our Service ✔️ Rapid Prototyping: 24-hour turnaround for urgent projects

✔️ Versatile Production: From 1 prototype to 100,000+ units

✔️ Guaranteed Quality: International-standard inspections with NDT reports

✔️ Real Factory Pricing: Transparent quotes with no hidden costs

✔️ Global Recognition: Trusted by 3000+ customers across 30+ countries

E-MAIL: info@hms1688.com

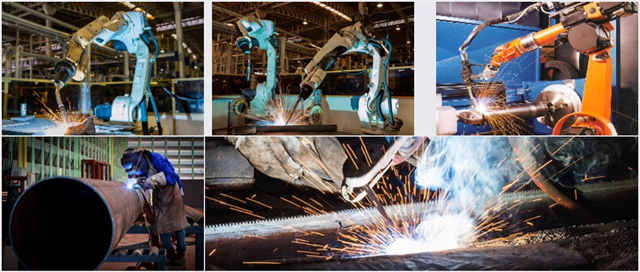

At HONGMING SHENG, we specialize in both robotic and manual precision welding. Whether it’s lightweight aluminum, thick mild steel, or corrosion-resistant stainless steel, our team delivers stable, beautiful, and strong welds tailored to your exact specifications.

Looking for expert Welding & Bending services? Our factory provides precision welding and CNC bending solutions with high efficiency and reliable quality.

We operate with certified welders, robotic welding arms, and advanced CNC bending machines — capable of handling small batch to high-volume production in aluminum, carbon steel, stainless steel, and brass.

Our process includes robotic welding, MIG/TIG welding, multi-axis positioning, and complete in-house quality inspection to meet international standards.

Whether you're fabricating a single bracket or a full-scale assembly, we ensure fast turnaround, cost-effective results, and technical support throughout the project.

Contact us today to receive a personalized welding and bending quote tailored to your drawings.

E-MAIL: info@hms1688.com

We invest in our customers by investing in our equipment and craftsmen. Our capabilities and main equipment include:

Contact us and just send us your drawing (SolidWorks,ProE,CAD,PDF,DXF...)

Links: Metal Stamping Services | Sheet Metal Fabrication Services | precision cnc machining and milling services | Metal Welding Services | metal Cutting Services | Metal Bending Service | Sheet Metal Enclosure Fabrication | Surface Finishing |