Postion: Home > Our Service >

Our Service

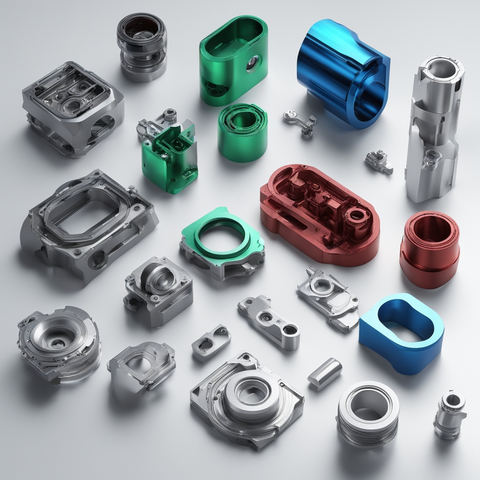

Our ServiceAt Hongming Sheng, we solve your biggest headaches in CNC machining: unstable lead times, poor QC, inconsistent suppliers, and hidden outsourcing. As a real ISO 9001:2015 certified factory, we offer direct manufacturing with on-time delivery and full quality assurance. Trusted by over 3000 clients across Europe, Southeast Asia, and Korea.

Processes: CNC turning, CNC milling, boring, drilling, grinding, wire-cutting

Materials:

- Aluminum (6061-T6, 7075-T6, 5052)

- Brass / Copper / Bronze

- Stainless Steel (304, 316, 420)

- Carbon Steel (Q235, 20#, 45#)

- Plastics (POM, PC, PE, ABS, Acrylic)

Surface Finishes: Anodizing, powder coating, sandblasting, plating, polishing, black oxide

Tolerances: Milling/Turning: ±0.005mm, Grinding: ±0.003mm, EDM: ±0.002mm

Our workshop is equipped with multi-axis CNC machines, automatic tool changers, and inspection tools to handle both custom prototypes and high-volume parts.

Machines Show

Production Process

Every product is individually inspected using CMM, height gauges, profile projectors, and micrometers. We issue full inspection reports with every shipment.

We manufacture parts for Automotive, Aerospace, Medical Devices, Industrial Equipment, Electronics, and Robotics. Our components are used in thousands of assemblies around the world.

Still comparing suppliers? Send us your drawing for a free review →

Your designs are protected. We never share files without permission and gladly sign NDAs. All data is managed securely within our factory.

Welcome to visit our Shenzhen factory anytime — real machines, real people, real production.

Contact us and just send us your drawing (SolidWorks,ProE,CAD,PDF,DXF...)

Links: Metal Stamping Services | Sheet Metal Fabrication Services | Precision CNC Machining / CNC Milling Services | Metal Welding Services | metal Cutting Services | Metal Bending Service | Surface Finishing | Sheet Metal Enclosures Housing Box And Case Fabrications |